October 4, 2024

Shop3D Case Study - Increasing Margins, Efficiency & Morale

“Deploying AutoQuote3D as the backbone of Shop3D’s print service offerings has allowed us to be a serious contender to service bureaus. We’ve saved hundreds of man-hours and generated thousands of dollars in additional orders. We highly recommend this tool for ANY 3D printing service.” - Jacky Wan, Co-founder & Chief Technical Officer, Shop3D.ca

At Shop3D.ca, printing services have always been something we’ve offered ‘on the side’. Our main business has always focused on sales and service of 3D Printers and consumables for major brands like Formlabs, Bambu Lab, Ultimaker, and Raise3D within the Canadian market. So there has always been a lot on our plate.

Shop3d Vancouver Showroom - While we have many printers in the showroom, actual production becomes more challenging as each printer has different build volumes, requirements, and materials available. AQ3D helps simplify the quoting process on different printing technologies like SLS, SLA and FFF with customizable material and process costing structures.

Our team always wants to be printing and learning, so naturally we have come up with a service we call "bridge printing". Essentially, customers who either have run out of capacity, have a printer down, or just need a few prints with another 3D printing technology are able to send us files and have us print them on our FDM, SLA or SLS machines. The main intention of this service was to support our existing customer base to help them out of a bind, but overtime we've attracted new customers requesting prints, and we certainly don't turn them away if we had print farm capacity.

Though this makes simple sense, the actual workflow and administrative load was a drag on our team.

The major pain points we encountered were:

- Overwhelming manual effort spent on back and forth with prospects just to get the information required to start a quote. This includes getting the file, asking them which technology they wanted to use, where they were located for taxes, and if they even knew what material they desired to use.

- Wasting a lot of manual quoting time for prospects that were not familiar with 3D printing and didn’t expect what the costs would be. Meaning that only a fraction of the quotes we provided actually proceeded to the printing point. Therefore, we would spend just as much time on quotes that would never convert.

- Juggling excel spreadsheets with complicated formulas to calculate starting costs + material costs + margins while constantly throwing prints into different slicers to grab material costs to plug in.

- Having no workflow management designed specifically for printing, which meant that the print team was not automatically notified if a customer paid for a print job, and therefore the print couldn't get started. All communication with customers was manual with respect to providing estimated print times for prints that were in process, finished, or ready for pick-up/shipping.

- Having multiple different platforms, apps, and documents to quote/send invoices and check status which meant a lot more mental overhead to keep everything organized and on track.

- Generally seeing longer delays in getting urgent quotes sent to customers.

At one point, frustrations boiled over during a busy period which forced us to temporarily pause all printing services between both locations. Eventually we invested in customizing software apps and new team procedures requiring a full team re-training. I’m certain that if we had designed our business from the ground up to be a printing service, we’d have more of this process pat down. Printing was a much smaller part of our operation back then, which we ultimately did feel was essential and beneficial to our customer base.

Even with our optimization, the process was still far from perfect, but AutoQuote3D was a great solution to many of our pain points. The most important and main reason for adopting this software solution was it’s primary namesake feature which was it’s function as an automatic quoting tool.

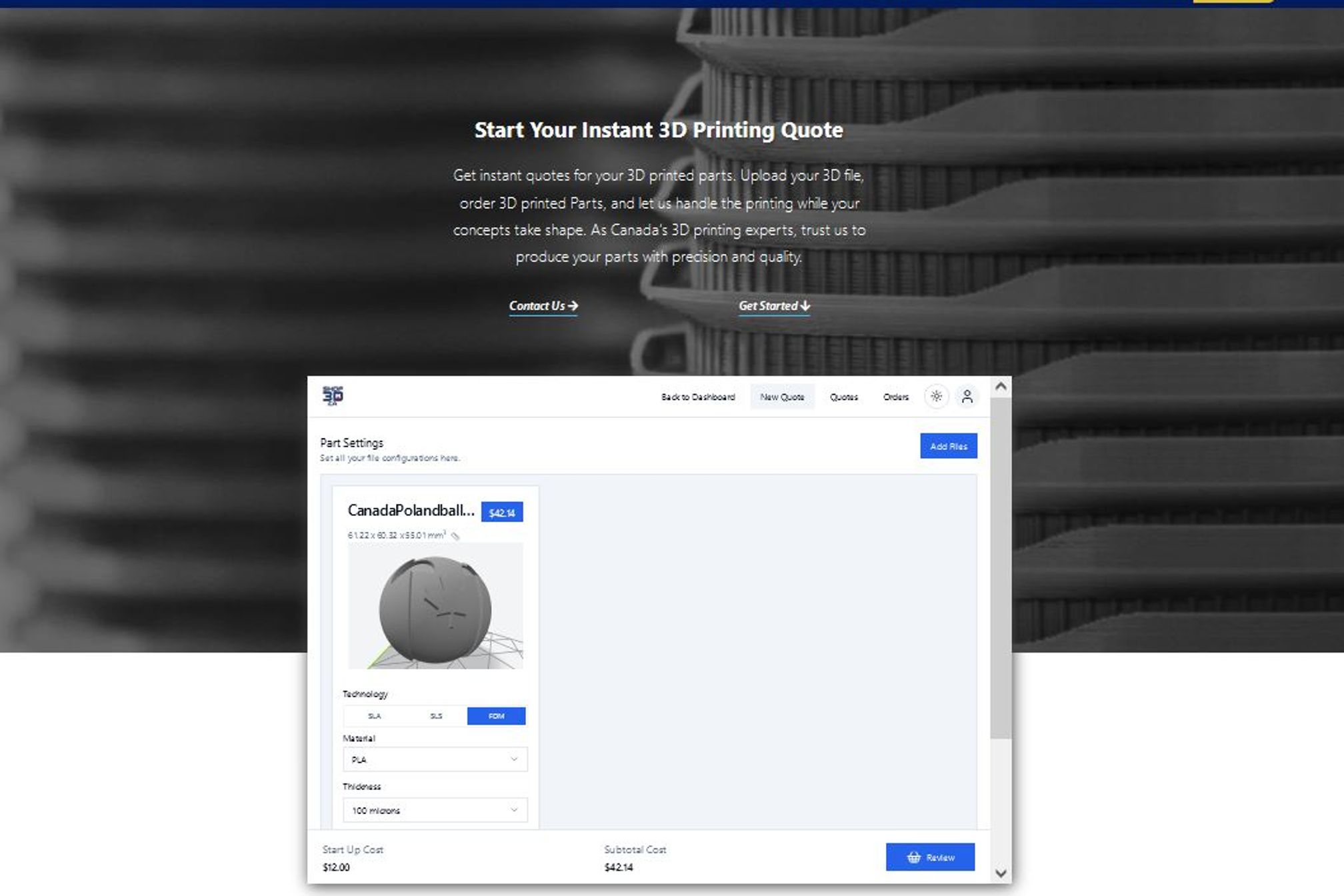

Quoting interface - Once the customer imports their model, they can choose all the settings and process and see the dynamic price change. If an exception occurs (like the file is too large, price is too high, or a lot of units) it can be automatically set to request a manual quote.

By implementing the AutoQuote3D system, we instantly addressed our biggest time and labor expense by eliminating the need for manual quoting and information collection. - Jacky Wan, Co-founder & Chief Technical Officer, Shop3D.ca

After a simple setup and onboarding, we added the quoting tool to our site, enabling customers to upload files directly to Shop3D and bypassing email inquiries and wait times. Customers were able to select printing technology, materials, provide shipping details for tax calculation, and include notes or expedited requests. Once the required information was entered, an instant quote was generated, allowing customers to decide if it fit their timeline and budget. This automation eliminated manual intervention, providing quick quotes to those who needed them, while those over budget were able to exit without human interaction.

This was a stark comparison to our manual process which required techs to gather customer details, request STL files, and confirm technology and material preferences. They would then upload the file to a slicer, record time and material costs, input those into a custom Excel sheet to calculate the price, and draft a manual quote in the CRM or shopping system. After entering customer information, the quote would be emailed, often followed by back-and-forth revisions and explanations. This process typically took at least two hours and could stretch over several days for customers who were less tech savvy. Often, our team would be left without a response, with the time and effort invested in preparing the quote going to waste.

Workflow - How our workflow has changed is dramatic. AutoQuote3D replaces the need for layers of different software interactions where we would have to manually curate. It even sends out a quick email to customers when you’ve changed the status from printing to shipping and any stages in between. Keeping everything within one software environment including some status update emails.

The embedded AutoQuote3D interface is now clearer and more universal so customers who do not have the requisite information, such as a ready 3D file, would not be quoted. That’s exactly what we want to see since we DO want to exclude prospects who do not have a 3D file ready and are not willing to provide their supplementary requirement information. These customers can contact us through other channels and may be routed to a design team instead of the prints team.

Once AQ3D was deployed, we no longer wasted time on quotes that wouldn't convert and have decreased our quoting time from ~4 hours down to nearly instantaneous. This speed and accuracy means that prospects would be more likely to go with a firm quote rather than wait for a back and forth with another competitor.

Overall, our team has praised the AutoQuote3D print management system as it allows them to focus on their work of printing rather than focus on menial administrative tasks of sending updates.

Less Admin = More printing! which means more experimentation, experience and knowledge for our team. A full sized SLA print on the new Form4 to test out its capabilities.

As we swapped over to the AutoQuote3D workflow which was designed for printing, each customer order followed and flowed down a pipeline showing the number of orders at each stage. It allowed our printing techs to readily identify the number of orders and prints they expected to be servicing in the short term while anticipating the next order in the queue.

Order organization - AQ3D organizes orders at all stages so you can easily see at a glance how many are paid and pending to how many are abandoned at the checkout. We can then reach out to see if we can convert the abandoned checkouts or gather more information to see if it’s too expensive, or didn’t have the material they requested etc.

At each critical stage, for example when an order moves from invoiced to paid, AutoQuote3D notifies the print team that the order is confirmed and ready for processing. This allows us to start preparing the print immediately. As we work on the order, the system automatically updates the customer on the progress, maintaining continuous communication to ensure the best possible customer experience. This real-time synchronization between our print teams and customers is crucial, as it aligns expectations at every step, from order preparation to pickup or shipping.

AutoQuote3D has completely transformed how Shop3D handles its print-to-order business. It has increased our sales by providing instant, accurate quotes that prospects can act on immediately. Costs have been reduced by eliminating the manual back-and-forth between techs and prospects, and by automatically filtering out those who don’t meet the budget requirements, saving our team valuable time. It has centralized our printing operations on a workflow tailored specifically to printing, rather than forcing us to adapt a product-focused system. Team collaboration has improved, our reporting and print queue are clearer, and customers are consistently informed about the status of their prints. For a simple monthly subscription and minimal setup, we’ve saved hundreds of man-hours and generated thousands of dollars in additional orders. This is a tool we highly recommend for ANY 3D Printing service.

With less admin, we’re happier to be more focused on printing and learning rather than paper pushing. We might be going a little too hard on the fun stuff…